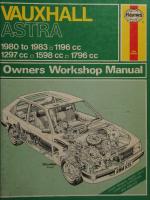

Haynes Dodge Colt/Plymouth Champ Owners Workshop Manual 1850103895, 9781850103899

“"1978 thru 1987. All front-wheel drive models"--Cover Includes index”.

178 44 25MB

English Pages 324 Year 1987

Polecaj historie

- Author / Uploaded

- P. G. Strasman

- John H. Haynes

- Categories

- Technique

- Transportation: Cars, motorcycles

Citation preview

DODGE colt PLYMOUTH champ

30016

(610)

1978 thru 1987 front-wheel drive models 97.5 cu 89.6 cu in (1.5 liter)

All

86 cu

in (1.4 liter)

in (1.6 liter)

Automotive Repair Manual

Digitized by the Internet Archive in

2012

http://archive.org/details/dodgecoltplymoutOOstra

Dodge Colt Plymouth Champ

Automotive Repai r

Manual by Peter G Strasman and John H Haynes Member

MISTC MIAM

of the Guild of Motoring Writers

Models covered Dodge Colt/Plymouth Champ

front

wheel drive Hatchback

models Does not cover

ISBN

©

1

rear

wheel drive models

85010 389 5

Haynes North America, With permission from

J. H.

Inc.

Haynes & Co.

1981, 1983, 1987

Ltd.

reserved. No part of this book may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying, recording or by any information storage or retrieval system, without permission in writing from the copyright holder. All rights

Printed

in

the

USA

(10W7

-

610)

AUTOMOTIVE

_^^%

ASSOCIATION

Haynes Publishing Group Sparkford Nr Yeovil Somerset BA22 7JJ England Library of

Haynes North America, 861 Lawrence Drive

Newbury Park California

91320

Congress

Inc Catalog card number

87-80384

USA

Acknowledgements Thanks are due to the Chrysler Corporation of the USA for the supply of technical information and certain illustrations, to Castrol Limited who supplied the lubrication data and to the Champion Sparking Plug Company who supplied the illustrations showing the

About /ts

this

manual

aim

the Section they are

The aim of this manual is to help you get the best value from your car. It can do so in several ways. It can help you decide what work must be done (even should you choose to get it done by a garage), provide information on routine maintenance and servicing, and give a logical course of action and diagnosis when random faults occur. However, it is hoped that you will make full use of the manual by tackling the work yourself. On simpler jobs it may even be quicker than booking the car into a garage, and having to go there twice, to leave and collect it. Perhaps most important, a lot of money can be saved by avoiding the costs the garage must charge to cover its labour and overheads.

The manual has drawings and descriptions to show the function of the various components so that their layout can be understood. Then the tasks are described and photographed in a step-by-step sequence so that even a novice can do the work. Its

arrangement The manual

various spark plug conditions. The bodywork repair photographs used in this manual were provided by Holt Lloyd Limited who supply Turtle Wax', Dupli-Color Holts' and other Holts range products.

divided into thirteen Chapters, each covering a The Chapters are each divided into Sections, numbered with single figures, eg 6; and the Sections into paragraphs (or sub-sections), with decimal numbers following on from is

logical sub-division of the vehicle.

Introduction to the Dodge Colt and Plymouth Produced in Japan and imported into North America by the Chrysler Corporation these vehicles are two of the most European styled cars yet to leave the Mitsubishi factories. Although the unique Power/Economy speed range is the most

It

is

in,

eg 5.1, 5.2, 5.3

etc.

freely illustrated in those parts

sequence

where there

of operations to be carried out.

is

a detailed

There are two forms of

illustration: figures and photographs. The figures are numbered in sequence with decimal numbers, according to their position in the Chapter: eg, Fig. 6.4 is the 4th drawing/illustration in Chapter 6. Photographs are numbered (either individually or in related groups) the same as the Section or sub-section of the text where the operation

they

show

is

described.

There is an alphabetical index at the back of the manual as well as a contents list at the front. References to the left' or right' of the vehicle are in the sense of a person in the driver's seat facing forwards. Unless otherwise stated nuts and bolts are tightened by turning clockwise and removed by turning anti-clockwise. Vehicle manufacturers continually make changes to specifications and recommendations, and these when notified are incorporated into our manuals at the earliest opportunity. Whilst every care is taken to ensure that the information in this manual is correct, no liability can be accepted by the authors or publishers for loss, damage or injury caused by any errors in, or omissions from, the information given.

Champ obvious feature of the cars the ease of maintenance must not be overlooked. The cars are well built and finished and have adequate passenger

and luggage accommodation.

Contents

Page

Acknowledgements About

this

2 2

manual

Dodge

Introduction to the

Colt and Plymouth

Champ

2

General dimensions, weights and capacities

5

Use of English

6

Buying spare parts and vehicle identification numbers

7

Tools and working

9

facilities

Jacking and towing

11

Safety

12

first!

Routine maintenance

13

Recommended

15

lubricants and fluids

Fault diagnosis

16

Chapter

19

1

Engine

65

Chapter 2

Cooling, heating, ventilation and

Chapter 3

Fuel,

Chapter 4

Ignition

Chapter 5

Clutch

112

Chapter 6

Manual and automatic transmissions

117

air

conditioning systems

exhaust and emission control systems

78 103

system

Chapter 7 Driveshafts

143

Chapter 8

Braking system

147

Chapter 9

Electrical

system

162

Chapter 10

Steering

200

Chapter

Suspension

210

1 1

Chapter 12

Bodywork and

Chapter 13 Supplement:

fittings

Revisions and information on 1981 and later North American models

222

240

Conversion factors

314

Index

315

1980 Dodge Colt RS

1980 Plymouth Champ Custom

V.

General dimensions, weights and capacities Refer to Chapter 13 for Specifications applicable to 1981 and later North American models

Dimensions 156.9 in (3985 mm) 62.4 in (1585 mm) 50.6 in (1285 mm) 90.6 in (2300 mm) 53.9 in (1370 mm) 52.8 in (1340 mm)

Overall length Overall width Overall height

Wheelbase Front track

Rear track

Weights Curb weight:

Models with manual transaxle Models with automatic transaxle

Maximum

trailer

weight

1808 1860 1543

lb lb lb

(820 (844 (700

kg) kg)

kg)

Capacities Engine

oil:

With filter change Without filter change Manual transaxle oil Automatic transaxle fluid From dry At routine change Fuel tank Cooling system

Imp Imp 4.0 Imp

3.7

6.2

pt (3.5

5.3

pt (3.0 litres. 3.2

10 Imp

litres,

pt (2.3 litres, 2.4 pt (5.7 litres, 6.0

8.0 Imp pt (4.5 8.8 Imp gal (40 8.8 Imp pt (5.0

litres,

litres,

litres,

US US US US

qt) qt) qt)

qt)

4.8 US qt) 10.6 US gal) 5.3 US qt)

Use of English As

this

book has been

written in England,

it

list

may use some

difficulty,

but to

make

of these differ from

sure, a glossary is printed below. In ordering spare parts

remember the parts

of these words:

English

American

English

Accelerator Aerial

Gas pedal Antenna

Locks Methylated

Anti-roll bar

Stabiliser or

Big-end bearing Bonnet (engine cover)

Rod bearing Hood

Boot (luggage compartment) Bulkhead

Trunk

Bush

Cam

Some

uses the appropriate English component names, phrases, and spelling.

those used in America. Normally, these cause no

follower or tappet

sway

bar

American Latches

Denatured alcohol

spirit

Motorway Number plate

Freeway, turnpike etc License plate

Paraffin

Kerosene

Petrol

Gasoline (gas)

Firewall

Petrol tank

Gas tank

Bushing

'Pinking'

'Pinging'

Valve

lifter

or tappet

Prise (force apart)

Pry

Carburettor

Carburetor

Propeller shaft

Driveshaft

Catch

Latch

Quarterlight

Quarter

Choke/venturi

Barrel

Retread

Circlip

Snap-ring

Reverse

Recap Back-up

Clearance

Lash Ring gear (of differential)

Rocker cover Saloon

Valve cover

Crownwheel Damper

Shock absorber, shock

Seized

Frozen

Disc (brake)

Rotor/disk

Sidelight

Parking light

Distance piece

Spacer Pitman arm

Silencer

Muffler

Convertible

Small end,

Dynamo

Generator (DC)

Spanner

Earth (electrical)

Ground

Split cotter (for valve spring

Engineer's blue

Prussian blue

Split pin

Cotter pin

Estate car

Station

Steering arm

Spindle arm

Exhaust manifold

Header

Sump

Oil

Fault finding/diagnosis

Troubleshooting

Metal chips or debris Valve

Drop arm Drop head coupe

wagon

Sill

window

Sedan

Rocker panel

panel (beneath doors) little

end

Piston pin or wrist pin

Wrench cap)

Lock

(for valve spring retainer)

pan

Free-play

Lash

Swarf Tab washer Tappet

Freewheel

Coast

Thrust bearing

Throw-out bearing

Gearbox Gearchange Grub screw

Transmission

Top gear

High

Shift

Torch

Flashlight

Setscrew, Allen screw

Trackrod (of steering)

Tie-rod (or connecting rod)

Float

chamber

Gudgeon

bowl

Float

shoe

Tang

or lock lifter

Secondary shoe

Piston pin or wrist pin

Trailing

Halfshaft

Axleshaft

Transmission

Whole

Handbrake

Parking brake

Tyre

Tire

Hood

Soft top

Van

Panel

Hot spot

Heat

Vice

Vise

Indicator

Turn signal

Wheel nut

Lug nut

Interior light

Dome lamp

Windscreen

Layshaft (of gearbox)

Countershaft

Wing/mudguard

Windshield Fender

Leading shoe (of brake)

Primary shoe

pin

riser

(of brake)

drive line

wagon/van

Buying spare parts and vehicle identification

numbers

Buying spare parts Replacement parts are available from many sources, which genfall into one of two categories -authorized dealer parts departments and independent retail auto parts stores. Our advice

erally

concerning these parts is as follows: Retail auto parts stores: Good auto parts stores will stock frequently needed components which wear out relatively fast, such as clutch components, exhaust systems, brake parts, tune-up parts, etc. These stores often supply new or reconditioned parts on an exchange basis, which can save a considerable amount of money. Discount auto parts stores are often very good places to buy materials and parts needed for general vehicle maintenance such as oil, grease, filters, spark plugs, belts, touch-up paint, bulbs, etc. They also usually sell tools and general accessories, have convenient hours, charge lower prices and can often be found notfarfrom home. Authorized dealer parts department: This is the best source for parts which are unique to the vehicle and not generally available elsewhere (such as major engine parts, transmission parts, trim pieces, ty,

etc.).

Warranty information: If the vehicle is still covered under warranbe sure that any replacement parts purchased - regardless of the

PAINT

source - do not invalidate the warranty! To be sure of obtaining the correct parts, have engine and chassis numbers available and, if possible, take the old parts along for positive identification.

Vehicle identification

numbers

Modifications are a continuing and unpublicised process in vehicle manufacture. Spare parts manuals and lists are compiled on a numerical basis, the individual numbers being essential to identify correctly the component required. The vehicle identification plate\s located on top of the facia panel crash pad just inside the windshield. The digits can be decoded as shown in the illustration. The engine numberls stamped on a machined surface at the side of the exhaust manifold. The chassis (body) numberls located on the engine compartment rear bulkhead (firewall).

The body colour number label is affixed to the front left-hand wing valance (photo). The transaxle number is stamped on the clutch housing part of the transaxle case.

CODE 090 VEL10W

Paint colour label

Vehicle identification plate location

">v

4H24KA 430001

Car

line

4 -Dodge 1

-Plymouth

1st

2nd

Digit

Digit

Price class

3rd

Body type

M— Medium

24—2 door

H-High

hatch back

for U.S.A.

&

4th

Digits

5th

6th

7th

8th

Digit

Digit

Digit

Digit

Engine displacement

J-1400c.c. (86.0 CID)

Model year

9-1979

A-1980

K-1600c.c. (97.5 CID)

5

1

-Plymouth

9th to 13 th

^

Digits

49 States

2— Medium Dodge

4-4x2 Speed M/T 7—3 speed A/T California

(for Canada)

Trim code

Transmission code

3 -High

4 -High

5—4x2 speed

M/T 8-3 speed A/T Canada

6-4x2 speeu M/T 9.-3 speed A/T

1

Dodge 1

Plymouth 5

-High 2 Dodge

8-High 2 Plymouth

9— Medium Plymouth

NOTE: M/T is an abbreviation for manual transmission. A/T is an abbreviation for automatic transmission. Vehicle identification plate interpretation

Vehicle body

^

number

Engine number location

Sequence

number

Tools and working

facilities

Introduction

A selection of good tools is a fundamental requirement for anyone contemplating the maintenance and repair of a motor vehicle. For the owner who does not possess any, their purchase will prove a considerable expense, offsetting some of the savings made by doing-it-yourself. However, provided that the tools purchased meet the relevant national safety standards and are of good quality, they will last for many years and prove an extremely worthwhile investment. To help the average owner to decide which tools are needed to carry out the various tasks detailed in this manual, we have compiled three lists of tools under the following headings: Maintenance and minor repair. Repair and overhaul, and Special. The newcomer to practical mechanics should start off with the Maintenance and minor repair tool kit and confine himself to the simpler jobs around the vehicle. Then, as his confidence and experience grow, he can undertake more difficult tasks, buying extra tools as, and when, they are needed. In this way, a Maintenance and minor repair tool kit can be built-up into a Repair and overhaul tool kit over a considerable period of time without any major cash outlays. The experienced do-ityourselfer will have a tool kit good enough for most repair and overhaul procedures and will add tools from the Special category when he feels the expense is justified by the amount of use these tools will be put to. It is obviously not possible to cover the subject of tools fully here. For those who wish to learn more about tools and their use there is a book entitled How to Choose and Use Car Tools available from the publishers of this manual. Maintenance and minor repair

tool kit

should be considered as a minimum requirement if routine maintenance, servicing and minor repair operations are to be undertaken. We recommend the purchase of combination spanners (ring one end, open-ended the other); although more expensive than open-ended ones, they do give the advantages of both types of spanner.

The

tools given in this

list

Combination spanners - 10, 11, 12, 13, 14 & 17 Adjustable spanner - 9 inch Spark plug spanner (with rubber insert) Spark plug gap adjustment tool Set of feeler gauges Brake bleed nipple spanner Screwdriver - 4 in long x j in dia (flat blade} Screwdriver - 4 in long x j in dia (cross blade) Combination pliers - 6 inch

Hacksaw

mm

(junior)

Tyre pump Tyre pressure gauge

Fine emery cloth (1 sheet)

Wire brush (small) Funnel (medium size)

Ball pein

hammer

Soft-faced hammer, plastic Screwdriver - 6 in long x ^ Screwdriver - 2 in long x ^ Screwdriver - 1\ in long x Screwdriver - 3 in long x j Pliers

-

or rubber in dia (flat blade) in

\

square in dia

(flat

blade)

(cross blade)

in dia (electricians)

electricians side cutters

Pliers

-

needle nosed

Pliers

-

circ/ip (internal

Cold chisel

-

-j

and

external)

inch

Scriber

Scraper Centre punch Pin

punch

Hacksaw Valve grinding tool Steel rule/straight-edge Allen keys Selection of files

Wire brush (large) Axle-stands

Jack (strong scissor or hydraulic type)

Special tools The tools in this list are those which are not used regularly, are expensive to buy, or which need to be used in accordance with their manufacturers' instructions. Unless relatively difficult mechanical jobs are undertaken frequently, it will not be economic to buy many of these tools. Where this is the case, you could consider clubbing together with friends (or joining a motorists' club) to make a joint purchase, or borrowing the tools against a deposit from a local garage or tool hire specialist.

The following list contains only those tools and instruments freely available to the public, and not those special tools produced by the

case and the relevant tool cannot be bought or borrowed you work to a franchised garage.

kit

be found invaluable as they are so versatile

particularly if various the j in square-drive type, as this can be used with most proprietary torque spanners. If you

the set.

Torque wrench (for use with sockets) Mole wrench - 8 inch

to entrust the

These tools are virtually essential for anyone undertaking any major repairs to a motor vehicle, and are additional to those given in the Maintenance and minor repair list. Included in this list is a comprehensive set of sockets. Although these are expensive they will in

list

its dealer network. You will find occasional references to these manufacturers' special tools in the text of this manual. Generally, an alternative method of doing the job without the vehicle manufacturers' special tool is given. However, sometimes, there is no alternative to using them. Where this is the

Grease gun can

drives are included

(or box spanners) to cover range in previous Reversible ratchet drive (for use with sockets) Extension piece, 10 inch (for use with sockets) Universal joint (for use with sockets)

Sockets

vehicle manufacturer specifically for

Oil

Repair and overhaul tool

cannot afford a socket set, even bought piecemeal, then inexpensive tubular box wrenches are a useful alternative. The tools in this list will occasionally need to be supplemented by tools from the Special list.

We

-

recommend

Valve spring compressor Piston ring compressor Balljoint separator Universal hub/bearing puller Impact screwdriver Micrometer and/or vernier gauge Dial gauge Stroboscopic timing light

will

have

Tool and working

10

Jaw gap

Dwell angle meter/tachometer Universal electrical multi-meter Cylinder compression gauge Lifting tackle (photo) Trolley jack Light with extension lead

Buying tools For practically all tools, a tool factor is the best source since he will have a very comprehensive range compared with the average garage or accessory shop. Having said that, accessory shops often offer excellent quality tools at discount prices, so it pays to shop around. There are plenty of good tools around at reasonable prices, but always aim to purchase items which meet the relevant national safety If in doubt, ask the proprietor or manager of the shop for advice before making a purchase.

standards.

Care and maintenance of tools Having purchased

a

reasonable tool

kit,

it

is

necessary to keep the always wipe off any

tools in a clean serviceable condition. After use,

grease and metal particles using a clean, dry cloth, before putting them lying around after they have been used. A simple tool rack on the garage or workshop wall, for items such as screwdrivers and pliers is a good idea. Store all normal spanners and sockets in a metal box. Any measuring instruments, gauges, meters, etc, must be carefully stored where they cannot be dirt,

the tools away. Never leave

damaged Take

or a

become

little

care

rusty.

when

tools are used.

become marked and screwdrivers

Hammer heads

inevitably

edge on their blades from time to time. A little timely attention with emery cloth or a file will soon restore items like this to a good serviceable finish. lose the keen

Working If

facilities Not to be forgotten when discussing tools, is the workshop anything more than routine maintenance is to be carried out,

itself.

some

working area becomes essential. It is appreciated that many an owner mechanic is forced by circumstances to remove an engine or similar item, without the benefit of a garage or workshop. Having done this, any repairs should always be done under the cover of a roof. Wherever possible, any dismantling should be done on a clean flat workbench or table at a suitable working height. Any workbench needs a vice: one with a jaw opening of 4 in (100 mm) is suitable for most jobs. As mentioned previously, some clean dry storage space is also required for tools, as well as the lubricants, cleaning fluids, touch-up paints and so on which become necessary. Another item which may be required, and which has a much more general usage, is an electric drill with a chuck capacity of at least ^ in (8 mm). This, together with a good range of twist drills, is virtually essential for fitting accessories such as wing mirrors and reversing form

of suitable

lights.

always keep a supply of old newspapers and rags available, and try to keep any working area as

Last, but not least,

clean, lint-free

clean as possible.

Jaw gap 0.250 0.276 0.313 0.315 0.344

(in)

Spanner i

in

mm

\

«'n

8 ]}'

size

AF AF; £

0.551

in

Whitworth

(in)

Spanner

1

mm

1

l

in

AF

^

in

Whitworth:

BSF

in

BSF

in

BSF

n

BSF

in

BSF

in

BSF

in

BSF

in

BSF

in

BSF

in

BSF

ji

in

BSF

1

in

BSF

mm

mm

0.600 0.625 0.630 0.669 0.686 0.709 0.710 0.748 0.750 0.813 0.820 0.866 0.875 0.920 0.938 0.945

| f

AF

in

mm

5

1

in

Whitworth; I

in

AF

1

6

1

7

mm mm

U in AF 18 mm | in Whitworth,

mm

19

in

AF AF

in

Whitworth; I

in

f || i|

mm

22

in

AF

in

Whitworth; £

in

AF

i | ||

mm

24 1

in

AF

|

in

Whitworth; |

mm

26

AF; 27 mm Whitworth; n

1,i in in

f

1-1 in

AF

mm

1.181

30

1.200 1.250 1.260 1.300 1.313 1.390 1.417 1.438 1.480 1.500 1.575 1.614 1.625 1.670 1.688

Whitworth; 1| in AF 32 mm % in Whitworth; 1| in AF j| in Whitworth;

1.811 1.813

in

mm

12 | in AF 1 3 } in Whitworth; 14

I

1.000 1.010 1.024 1.063 1.100 1.125

size

9 mm | in AF 10 mm

0.563 0.591

2.000 2.050 2.165 2.362

mm in

0.354 0.375 0.394 0.433 0.438 0.445 0.472 0.500 0.512 0.525

1.860 1.875 1.969

AF

7

facilities

ji

in

mm

36

1£ in AF | in Whitworth; 1^ in AF

mm

41

If 1

IS

46 1

1

55

60

in

BSF

AF

mm in

AF

U

in

BSF

in

BSF

mm

in

j

AF

Whitworth; 1£

in

,1

50 2

in

in

AF

in

Whitworth;

mm mm

Jacking and towing Jacking The jack supplied

in the car tool kit should only be used for roadwheel. Do not use this jack if working under the car unless it is supported on axle stands. When using a trolley, hydraulic or screw type jack for overhaul or repair operations, locate it only under the front and rear crossmembers or side frame. Never use a jack under the rear suspension crosstube. Always supplement the jacks with axle stands.

changing

a

down

during moving on a transporter although they can tow rope to another vehicle. If the car is equipped with automatic transmission, restrict any towing to a maximum distance of 15 miles (25 km) and to a road speed of 30 mph (50 km/h). tying the car

be used

to

for attaching a

If the automatic transmission is defective or longer distances are be covered then the front of the car must be raised by attaching

chains.

Towing The hooks provided

at the front

and rear of the car (photos) are

for

Whenever your car make sure that

vehicle,

being towed on its roadwheels by another the steering column is unlocked. is

a g

^>- ©) lHUff

()

Frame contact

(

floor

j

|acO

Scissors jack (emergency) locations

Vehicle jacking points

Front towing/lifting chain attachments

Front towing hook/jacking point

Rear towing hook

Safety

first!

Regardless of how enthusiastic you may be about getting on with the job at hand, take the time to ensure that your safety is not jeopardized. A moment's lack of attention can result in an accident, as can failure to observe certain simple safety precautions. The possibility of an accident will always exist, and the following points should not be considered a comprehensive list of all dangers. Rather, they are intended to make you aware of the risks and to encourage a safety conscious approach to all work you carry out on your vehicle.

Essential

DOs and DON'Ts

on a jack when working under the vehicle. Always use approved jackstands to support the weight of the vehicle and place them under the recommended lift or support points. DON'T attempt to loosen extremely tight fasteners (i.e. wheel lug nuts) while the vehicle is on a jack — it may fall. DON'T start the engine without first making sure that the transmission is in Neutral (or Park where applicable) and the parking brake is set. DON'T remove the radiator cap from a hot cooling system — let it cool or cover it with a cloth and release the pressure gradually. DON'T attempt to drain the engine oil until you are sure it has cooled

DON'T

rely

not burn you. DON'T touch any part of the engine or exhaust system until it has cooled sufficiently to avoid burns. DON'T siphon toxic liquids such as gasoline, antifreeze and brake fluid by mouth, or allow them to remain on your skin. DON'T inhale brake lining dust — it is potentially hazardous (see Asbestos below) DON'T allow spilled oil or grease to remain on the floor — wipe it up before someone slips on it. DON'T use loose fitting wrenches or other tools which may slip and to the point that

cause

it

will

injury.

DON'T push on wrenches when Always

loosening or tightening nuts or bolts.

wrench toward you. If the situation calls for pushing the wrench away, push with an open hand to avoid scraped knuckles if the wrench should slip. DON'T attempt to lift a heavy component alone — get someone to try to pull the

help you.

DON'T DON'T

rush or take unsafe shortcuts to finish a job. allow children or animals in or around the vehicle while you

are working on

it.

DO

wear eye protection when using power tools such as a drill, sander, bench grinder, etc. and when working under a vehicle. DO keep loose clothing and long hair well out of the way of moving parts.

DO make adequate

DO

get

sure that any hoist used has a safe working load rating for the job.

someone

a vehicle.

to

check on you periodically when working alone on ,

DO carry out

work in a logical sequence and make sure that everything is correctly assembled and tightened. DO keep chemicals and fluids tightly capped and out of the reach of children and pets. DO remember that your vehicle's safety affects that of yourself and others. If in doubt on any point, get professional advice.

by two metal surfaces contacting each other, or even by static up in your body under certain conditions, can ignite gasoline vapors, which in a confined space are highly explosive. Do not, under any circumstances, use gasoline for cleaning parts. Use an approved safety solvent. Always disconnect the battery ground (-) cable at the battery before working on any part of the fuel system or electrical system. Never risk spilling fuel on a hot engine or exhaust component. It is strongly recommended that a fire extinguisher suitable for use on fuel and electrical fires be kept handy in the garage or workshop at all times. Never try to extinguish a fuel or electrical fire with water. circuit,

electricity built

Torch (flashlight in the US) Any reference to a "torch" appearing in this manual should always be taken to mean a hand-held, battery-operated electric light or flashlight. It DOES NOT mean a welding or propane torch or blowtorch.

Fumes Certain fumes are highly toxic and can quickly cause unconsciousness and even death if inhaled to any extent. Gasoline vapor falls into this category, as do the vapors from some cleaning solvents. Any draining or pouring of such volatile fluids should be done in a well ventilated area.

When using cleaning fluids and solvents, read the instructions on the container carefully. Never use materials from unmarked containers. Never run the engine in an enclosed space, such as a garage. Exhaust fumes contain carbon monoxide, which is extremely poisonous. If you need to run the engine, always do so in the open air, or at least have the rear of the vehicle outside the work area. If you are fortunate enough to have the use of an inspection pit, never drain or pour gasoline and never run the engine while the vehicle is over the pit. The fumes, being heavier than air, will concentrate in the pit with possibly lethal results. The battery Never create a spark or allow a bare light bulb near a battery. They normally give off a certain amount of hydrogen gas, which is highly explosive.

Always disconnect the working on the

battery ground (-) cable at the battery before

systems. caps or cover when charging the battery from an external source (this does not apply to sealed or maintenancefree batteries). Do not charge at an excessive rate or the battery may If

fuel or electrical

possible, loosen the

filler

burst.

Take care when adding water to a non maintenance-free battery and carrying a battery. The electrolyte, even when diluted, is very corrosive and should not be allowed to contact clothing or skin. Always wear eye protection when cleaning the battery to prevent the caustic deposits from entering your eyes.

when

Mains electricity (household current in the US) When using an electric power tool, inspection light, etc., operates on household current, always

Asbestos Certain friction, insulating, sealing, and other products — such as linings, brake bands, clutch linings, torque converters, gaskets, etc. — contain asbestos. Extreme care must be taken to avoid inhalation of dust from such products since it is hazardous to health. If in doubt, assume that they do contain asbestos.

brake

sure that the tool is correctly connected to its plug and that, where necessary, it is properly grounded. Do not use such items in damp conditions and, again, do not create a spark or apply excessive heat in the vicinity of fuel or fuel vapor.

Secondary A

Fire at all times that gasoline is highly flammable. Never smoke have any kind of open flame around when working on a vehicle. But the risk does not end there. A spark caused by an electrical short

Remember

or

which

make

ignition

system voltage

severe electric shock can result from touching certain parts of the ignition system (such as the spark plug wires) when the engine is running or being cranked, particularly if components are damp or the insulation is defective. In the case of an electronic ignition system, the secondary system voltage is much higher and could prove fatal.

Routine maintenance Maintenance is essential for ensuring safety and desirable for the purpose of getting the best in terms of performance and economy from the car. Over the years the need for periodic lubrication - oiling, greasing and so on - has been drastically reduced if not totally eliminated. This has unfortunately tended to lead some owners to think that because no such action is required the items either no longer exist or will last forever. This is a serious delusion.

that the largest

This

may

Every

initial

element of maintenance

is

follows therefore visual examination. It

or

weekly

Check the tyre pressures when the tyres are cold (Chapter 1 1) Check the engine oil level and top up if necessary (photos) Check the battery and coolant levels (Chapters 2 and 9) Top up the washer fluid reservoir (photo) Check the operation of the lights, direction indicators and horn Check the operation of the windscreen and tailgate wipers

After the

Check Check Check Check Check Check Check Check Check

first

security

Check the operation

of emission control

2-way valve

the valve clearances (Chapter 1) the idle speed (Chapter 3) the dwell angle (mechanical distributor only) (Chapter 4) the ignition timing (Chapter 4)

3)

Renew

the

air

cleaner element (Chapter 3) of the ignition HT leads

Check the condition

Renew Renew

the drivebelts the carbon canister (early Californian models) (Chapter 3) Dismantle, clean and repack the rear hub bearings Change the manual transaxle oil (photos) (Chapter 6) Change the automatic transaxle fluid (Chapter 6)

Inspect the steering balljoints for wear, split dust excluders and the 11

rack bellows for deterioration (Chapter 10) Check the automatic choke and linkage for correct operation and

wear Check the

security of fuel

system pipes, hoses and the

filler

cap

seal

drivebelt tension

torque of the roadwheel nuts doors for positive closure gauze filter in the carburettor (Chapter 3)

Every 50 000 miles (80 000 km)

Check Check Check Check Check Check

Every 7500 miles (12 700 km)

Change the engine

oil

(not

filter)

Inspect the brake disc pads for wear (Chapter 8) Check the automatic transmission fluid level (Chapter 6) Clean the gauze filter in the carburettor (Chapter 3) Lubricate all the controls, hinges and locks

Every 15 000 miles (24

the operation of the air cleaner air intake valve the operation of the air switching valve the operation of the coasting air valve the operation of the thermo valve the operation of the purge control valve the operation of the two-way valve the carbon canister (late Californian models) (Chapter 3)

Renew

Every

1

2 months

Renew

the coolant in the engine cooling system air conditioner refrigerant and compressor checked (dealer operation)

000 km)

Have the

Change the engine oil and filter Check the valve clearances (Chapter 1) Check the engine idle speed (Chapter 3) Check the dwell angle (mechanical distributor) (Chapter Check the ignition timing (Chapter 4)

Renew Renew

(not Cali-

fornia) (Chapter 3)

Every 30 000 miles (48 000 km)

1000 miles (1600 km) - new cars only

the torque of the cylinder head bolts (cold) (Chapter 1) the torque of the exhaust manifold bolts (cold) (Chapter

the the the Clean the

the contact breaker points and condenser (Chater 4) the distributor cap and rotor Clean the crankcase emission control system components Inspect all the engine rubber hoses for deterioration Check all the evaporative emission control system connections for

Check the brake hydraulic system for fluid leakage Inspect the brake linings for wear (Chapter 8) Check the manual transmission fluid level (photo) (Chapter 6) Check the operation of deceleration fuel cut off system (Chapter

lead to repairs or renewals.

250 miles (400 km)

Renew Renew

(Chapter 3) the spark plugs the fuel

Clean

air

conditioner condenser fins

4)

Every 24 months

filter

Renew

the brake hydraulic fluid

(if

fitted)

oil

level

Engine

oil

dipstick markings

Coolant expansion tank (lower

left)

and washer fluid reservoir and

pumps

Topping up the engine

Manual transmission

oil

drain plug

Manual transmission

Filling

filler/levei

plug

the manual transmission

Recommended Component Engine

or

system

(1)

lubricants and fluids Lubricant type or specification

20W/50

engine

oil

Transaxle: (2)

Manual Automatic Wheel bearings (3) Steering rack (4)

Brake

fluid (5)

SAE 80

gear oil automatic transmission fluid J310a general purpose grease J310a general purpose grease

Dexron

II

SAE SAE SAE J1703e

hydraulic fluid

Note: The above are general recommendations only. Lubrication requirements vary from doubt consult your nearest dealer or the operator's handbook supplied with the vehicle.

territory to territory

and depend on

vehicle usage. If in

Fault diagnosis introduction The car owner who does his or her own maintenance according to the recommended schedules should not have to use this section of the manual very often. Modern component reliability is such that, provided those items subject to wear or deterioration are inspected or renewed at the specified intervals, sudden failure is comparatively rare. Faults do not usually just happen as a result of sudden failure, but develop over a period of time. Major mechanical failures in particular are usually preceded by characteristic symptoms over hundreds or even thousands of miles. Those components which do occasionally fail without warning are often small and easily carried in the car. With any fault finding, the first step is to decide where to begin investigations. Sometimes this is obvious, but on other occasions a little detective work will be necessary. The owner who makes half a dozen haphazard adjustments or replacements may be successful in curing a fault (or its symptoms), but he will be none the wiser if the fault recurs and he may well have spent more time and money than was necessary. A calm and logical approach will be found to be more satisfactory in the long run. Always take into account any warning signs or abnormalities that may have been noticed in the period preceding the fault - power loss, high or low gauge readings, unusual noises or smells, etc - and remember that failure of components such as fuses or spark plugs may only be pointers to some underlying fault. The pages which follow here are intended to help in cases of failure to start or breakdown on the road. There is also a Fault Diagnosis Section at the end of each Chapter which should be consulted if the preliminary checks prove unfruitful. Whatever the fault, certain basic principles apply.

what the symptoms

These are are follows:

simply a matter of being sure that you know are before starting work. This is particularly

Verify the fault. This

is

important if you are investigating a fault for someone else who may not have described it very accurately. Don't overlook the obvious. For example, if the car won't start, is there petrol in the tank? (Don't take anyone else's word on this particular point, and don't trust the fuel gauge either!). If an electrical fault is indicated, look for loose or broken wires before digging out the test gear.

Cure the disease, not the symptom. Substituting a flat battery with one will get you off the hard shoulder, but if the underlying cause is not attended to, the new battery will go the same way. Similarly, changing oil-fouled spark plugs for a new set will get you moving again, but remember that the reason for the fouling (if it wasn't simply an incorrect grade of plug) will have to be established a fully charged

and corrected. Don't take anything for granted. Particularly, don't forget that a component may itself be defective (especially if it's been rattling round in the boot for months), and don't leave components out of a fault diagnosis sequence just because they are new or recently fitted. When you do finally diagnose a difficult fault, you'll probably realise that all the evidence was there from the start. 'new'

Electrical faults can be more puzzling than straightforward mechanical failures, but they are no less susceptible to logical analysis if the basic principles of operation are understood. Car electrical wiring exists in extremely unfavourable conditions - heat, vibration and chemical attack - and the first things to look for are loose or corroded connections and broken or chafed wires, especially where the wires pass through holes in the bodywork or are subject to vibration. All metal-bodied cars in current production have one pole of the battery earthed', ie connected to the car bodywork, and in nearly all Electrical faults

modern cars it is the negative (-) terminal. The various electrical components motors, bulb holders etc - are also connected to earth, either by means of a lead or directly by their mountings. Electric current flows through the component and then back to the battery via the car bodywork. If the component mounting is loose or corroded, or if a good path back to the battery is not available, the circuit will be

incomplete and a malfunction

means

are also earthed by

subframe;

and

if

will result.

The engine and/or gearbox body or

of flexible metal straps to the

these straps are loose or missing, starter motor, generator

ignition trouble

may

result.

Assuming the earth return to be satisfactory, electrical faults will be due either to component malfunction or to defects in the current supply. Individual components are dealt with in Chapter 9. If supply wires are broken or cracked internally this results in an open-circuit, and the easiest way to check for this is to bypass the suspect wire temporarily with a length of wire having a crocodile clip or suitable connector at each end. Alternatively, a 12V test lamp can be used to verify the presence of supply voltage at various points along the wire and the break can be thus isolated. If a bare portion of a live wire touches the car bodywork or other earthed metal part the electricity will take the low-resistance path thus formed battery to the battery: this is known as a short-circuit. Hopefully a short-circuit will blow a fuse, but otherwise it may cause burning of the insulation (and possibly further short-circuits) or even a fire. This is why it is inadvisable to bypass persistently blowing fuses with silver foil or wire.

Spares and tool

kit

Most cars are only supplied with sufficient tools for wheel changing; the Maintenance and minor repair tool kit detailed in Tools and working facilities, with the addition of a hammer, is probably sufficient for those repairs that most motorists would consider attempting at the roadside. In addition a few items which can be fitted without too much trouble in the event of breakdown should be carried. Experience and available space will modify the list below, but the may save having to call on professional assistance.

following

Spark plugs, clean and correctly gapped lead and plug cap - long enough to reach the plug furthest from the distributor Distributor rotor, condenser and contact breaker points (mechanical breaker type distributor)

HT

Drivebe/tfs)

- emergency type may

Spare fuses Set of principal

light

Tin of radiator sealer

suffice

bulbs

and hose bandage

Exhaust bandage Roll of insulating tape

Length of soft iron wire Length of electrical flex Torch or inspection lamp (can double as

jump

Battery

test

lamp)

leads

Tow-rope Ignition waterproofing aerosol Litre of

engine

oil

Sealed can of hydraulic

fluid

If spare fuel is carried, a can designed for the purpose should be used to minimise risks of leakage and collision damage. A first aid kit and a warning triangle, whilst not at present compulsory in the UK, are

obviously sensible items to carry

When

in

addition to the above.

abroad it may be advisable to carry additional spares which, even if you cannot fit them yourself, could save having to wait while parts are obtained. The items below may be worth touring

considering:

Clutch and throttle cables Cylinder head gasket Alternator brushes

Fuel pump repair Tyre valve core

One

of

kit

the motoring organisations will

availability of fuel etc in foreign countries.

be able to advise on

Fault diagnosis

Correct

way

to connect

jump

leads.

Do

not allow car bodies to

17

Crank engine and check

for spark.

Note use

of insulated tool

touch!

A Check

for fuel delivery at carburettor

Other ignition system fault (see Chapter 4) Other fuel system fault (see Chapter 3) Poor compression (see Chapter 1) Major mechanical failure (eg camshaft drive)

Engine

fires

Insufficient

but

will

not run

choke (cold engine)

slack drivebelt can cause overheating and battery charging problems. Slacken arrowed bolts to adjust

Engine misfires before cutting out - fuel Fuel tank Fuel

fault

empty

pump

filter blocked (check for delivery) vent blocked (suction will be evident on releasing cap) Carburettor needle valve sticking Carburettor jets blocked (fuel contaminated) Other fuel system fault (see Chapter 3)

Fuel tank

defective or

filler

Air leaks at carburettor or inlet manifold

Fuel starvation (see Chapter 3) Ballast resistor defective, or other ignition fault (see Chapter 4)

Engine cuts out and

Engine cuts out - other causes Serious overheating Major mechanical failure (eg camshaft drive)

will not restart

Engine overheats

Engine cuts out suddenly - ignition

fault Loose or disconnected LT wires Wet HT leads or distributor cap (after traversing water splash) Coil or condenser failure (check for spark) (mechanical breaker system) Other ignition fault (see Chapter 4) Fault in electronic system component

Ignition (no-charge) warning light illuminated Slack or broken drivebelt - retension or renew Ignition warning light not illuminated Coolant loss due to internal or external leakage (see Chapter

2)

Fault diagnosis

18 Thermostat defective

Low

oil

Engine noises

level

Brakes binding Radiator clogged externally or internally Electric cooling fan not operating correctly Engine waterways clogged Ignition timing incorrect or automatic advance malfunctioning Mixture too weak

Pre-ignition (pinking) Ignition timing incorrect

Distributor faulty or

Worn

worn

or maladjusted carburettor

Excessive carbon build-up

Note:

Do

not add cold water to an overheated engine or

on acceleration

Incorrect grade of fuel

in

engine

damage may

result

Whistling or wheezing noises Leaking vacuum hose

Low engine

oil

Leaking carburettor or manifold gasket Blowing head gasket

pressure

Gauge reads low or warning light illuminated with engine running Oil level

Tapping or Worn Worn

low or incorrect grade

Defective gauge or sender unit Wire to sender unit earthed Engine overheating

rattling

Incorrect valve clearances

valve gear timing chain or belt

Broken piston

ring (ticking noise)

Knocking or thumping

clogged or bypass valve defective pressure relief valve defective Oil pick-up strainer clogged Oil pump worn or mountings loose Worn main or big-end bearings Oil filter

Unintentional mechanical contact (eg fan blades) fanbelt Peripheral component fault (generator, water pump etc) Worn big-end bearings (regular heavy knocking, perhaps less under

Oil

Worn

load)

Low

pressure in a high-mileage engine at tickover is not necessarily a cause for concern. Sudden pressure loss at speed is far

Worn main

more

Piston slap (most noticeable

Note:

oil

significant. In

any event, check the gauge or warning

before condemning the engine.

light

sender

bearings (rumbling and knocking, perhaps worsening under

load)

when

cold)

Chapter

Engine

1

Refer to Chapter 13 for Specifications applicable to 1981 and later North American models Contents

Part

A 1410

cc (86 cu

in)

engine

Camshaft - removal and refitting Crankshaft and main bearings - refitting Cylinder head - removal and refitting Emission control and overhaul operations (North American models) Engine - complete dismantling Engine - complete rebuilding Engine front casing and oil pump - removal and

5 15

6

24

refitting

Engine reassembly - general Engine sump - removal and refitting Engine/transmission - method of removal Engine/transmission — reconnection Engine/transmission - refitting Engine/transmission - removal Engine/transmission - separation Flywheel - refitting General description Initial start-up after major overhaul Major operations possible with engine in the car Oil filter - renewal Pistons and connecting rods - removal and refitting Rocker gear - removal and refitting Timing belt - renewal Valve clearance - adjustment (except North America) Valve clearance - adjustment (North America)

Part

B 1597 cc (97.5 cu

in)

13 17 8 14 7

10 18 22 1

1

12 16

Engine/automatic transmission - separation Engine/automatic transmission - refitting Engine/automatic transmission - reconnection Engine - complete dismantling Engine - complete reassembly

Part

2 21 9 3

General description Silent shafts - removal and refitting Toothed belts and sprockets - removal and

4 19

20

41

30 51

36 38 49 45 39 43

C 1597

D

Part

cc (97.5 cu

in)

refitting

E

Part

1410 2.91

3.23 9.0

in :

K 1597 cc (97.5 cu

(74,0 (82.0

in)

mm) mm)

3.03 3.39 8.5

1

in in :

(76.9 (86.0

in)

mm) mm)

1

Cylinder location and distributor rotation

ORDER -3-4-2

FIRING 1

©®(DO

FRONT

(No

1

at timing belt end)

0763H -X

Crankshaft 1.8898 1.6535

57 62 55 65 64 59 61

63

66

cc (86 cu in

60 58 56

Fault diagnosis

Fault diagnosis

4-cylinder in-line, overhead camshaft

Main journal diameter Crankpin diameter Maximum taper of crankpin or journals Crankshaft end-float Journal and crankpin undersizes Main bearing running clearance Connecting rod big-end bearing running clearance Side clearance

42 25 50 26 47 33 27 28 46

Examination and renovation

Camshaft and bearings Connecting rods and big-end bearings Crankcase, cylinder block and mountings Crankshaft and main bearings Cylinder head and valves - servicing and decarbonising Examination and renovation - general Flywheel and starter ring gear Front casing and oil pump Piston connecting rods and piston rings Rocker gear Timing belt, sprockets and tensioner

J

ratio

37

40 34

52 54 53

Engine (general)

Compression

31

44 35

engine with silent shafts

Specifications

Engine type Designation Capacity Bore Stroke

32 48

1

23

engine without silent shafts 29

Camshaft - removal and refitting Crankshaft and main bearings - refitting Cylinder head - removal and refitting Emission control and overhaul operations Engine/automatic transmission - removal

Engine front casing and oil pump - removal and refitting Engine/manual transmission - refitting Engine sump - removal and refitting Engine/manual transmission - reconnection Engine/manual transmission - removal Engine/manual transmission - separation Engine reassembly - general Engine/transmission - method of removal Flywheel (or driveplate - automatic transmission) - refitting General description Initial start-up after major overhaul Major operations possible with engine in car Oil filter - renewal Pistons and connecting rods - removal and refitting Rocker gear - removal and refitting Timing belt - renewal Valve clearance - adjustment

in

in

(48.0 (42.0

mm) mm)

2.2441 1.7717

in in

(57.0 (45.0

mm) mm)

0.0004 in (0.01 mm) 0.002 to 0.007 in (0.05 to 0.18 mm) 0.010, 0.020, 0.030 in (0.25, 0.50, 0.75 mm) 0.0008 to 0.0028 in (0.02 to 0.07 mm) 0.0004 to 0.0024 in (0.01 to 0.06 mm) 0.004 to 0.01 in (0.1 to 0.25 mm)

1

Chapter

20

1

Engine

Cylinder block Cast iron

Material

Maximum

0.0008

taper or out of round of cylinder bore

mm)

(0.02

in

Piston and piston rings 2.91 in (74.0 mm) 0.010, 0.020, 0.030, 0.039

Piston diameter Piston oversizes

Piston to bore clearance Clearance of piston ring

Top compression

in

Second compression

0.006

in

(0.15

mm)

0.0008

to

0.0016

in

0.0012

to

0.0028

in

mm)

mm)

(0.02 to 0.04

0.005

in

(0.12

0.039

in (0.1

mm)

(0.03 to 0.07 mm) in (0.10 mm)

0.004

ring:

Standard

0.0008

Maximum

to

0.0024

in

mm)

(0.02 to 0.06 mm) in (0.10 mm)

0.004

end gap:

0.008

Maximum Oil control ring side rail

0.016

mm)

0.4

in (0.2 to

0.039

mm)

in (0.1

end gap:

0.008 0.039

Maximum Oversize piston rings Compression pressures, with starter motor running, throttle open, coil HT lead disconnected variation

to

mm)

Standard

Maximum

(76.9

piston groove

Maximum

ring

in

ring:

Standard

Compression Standard

3.0276

(0.25, 0.50, 0.75, 1.00

in

0.020

to

mm)

0.5

in (0.2 to

mm)

in (0.1

0.010, 0.020, 0.030, 0.039

in

(0.25, 0.50, 0.75,1.00

mm)

full 2

149 lbf/in (10.48 kgf/cm 2 2 15 lbf/in (1.05 kgf/cm

between cylinders

2 )

)

Cylinder head Material

Maximum

Light alloy distortion of joint face

0.004

in (0.1

0.002

to

mm)

Camshaft Number

Three

of bearings Bearing running clearance Height of cam lobe:

Five

Intake

1.50

Exhaust

1.5039

Wear

in

limit

0.002

Camshaft endfloat

to

(0.05 to 0.09

in

mm) mm)

(38.1 in

0.0035

1.4331 1.4331

(38.2

0.020 0.008 in

in

(0.5

in

(36.4 (36.4

mm) mm)

mm) 0.002

mm)

(0.05 to 0.2

in

mm)

to

0.006

in

mm)

(0.05 to 0.15

Valves Clearance

(hot):

0.006 0.010

in

in

(0.15 (0.25

0.315 0.004

in

(8.0

Exhaust

0.31 5

in

Wear

0.006

in

Intake

Exhaust Stem diameter: Intake

Wear

limit

limit

Clearance of valve stem

in

0.0012 to 0.0024 in (0,03 to 0,06 mm) 0.004 in (0.1 mm) 0.002 to 0.0035 in (0.05 to 0.09 mm) 0.006 in (0.15 mm) 0.002, 0.010, 0.020 in (0.05, 0.25, 0.50 mm)

limit

Exhaust

Wear

mm) mm) (8.0 mm) (0.15 mm)

in (0.1

guide:

Intake

Wear

mm) mm)

limit

Valve guide oversizes Valve head edge minimum thickness after grinding

in:

Intake

0.028

in

(0.7

Valve stem diameter Seat angle Valve spring free length

0.039 in (1 .0

to

in

(1.0

mm)

mm)

0.051

0.12, 0.24

Type Free length Maximum reduction in free length before renewal Jet valves (North America): Valve clearance (hot)

mm) 0.039 0.035 45°

Exhaust Valve seat contact width Valve seat angle Oversize seat inserts Valve springs:

(0.9 to 1.3

in

in (0.3,

0.6

mm)

mm)

Coil

1.697

in

(43.1

mm) 0.039

1.823 in

(1.0

mm)

0.006 in (0.15 mm) 0.1693 in (4.300 mm)

45° 1.1654

in

(29.60

mm)

in

(46.3

mm)

Chapter

Engine

21

pump

Oil

Eccentric gear or trochoid rotor

Type Clearances (Eccentric gear): Outer gear and casing Crescent and outer gear Crescent and inner gear

0.0039 0.0087 0.0083 0.0016

Gear endfloat Clearances (Trochoid

Between

pressure

relief

to

to to to

0.0079 0.0134 0.0126 0.0039

in

to 0.2 mm) (0.22 to 0.34 mm)

in (0.1

in

(0.21 to 0.22

in

(0.04 to 0.10

mm) mm)

in

(0.04 to 0.12 (0.10 to 0.16 (0.06 to 0.12

mm) mm) mm)

rotor):

0.0016 0.0039 0.0024

tips of rotors

Outer rotor to pump cover Rotor endfloat Oil

1

1.850

valve free length

Torque wrench settings

to to to

in

0.0047 0.0063 0.0047

(47.0

in in

mm)

Nm

Ibf ft

Cylinder head bolts (cold engine):

Stage 1 Stage 2 Stage 3 Camshaft bearing cap bolts (1597 cc engine) Camshaft sprocket bolt Rocker cover bolts: 1410 cc engine 1 597 cc engine Main bearing cap bolts Connecting rod cap nuts Flywheel bolts Driveplate bolts (automatic transmission) Crankshaft pulley centre bolts Crankshaft pulley outer bolts Oil pump sprocket bolt (1597 cc engine)

Timing

cc engine)

Intake manifold bolts

Exhaust manifold bolts Exhaust downpipe flange bolts Front casing bolts: 1410 cc engine 1 597 cc engine Jet valves (North America) Rocker arm shaft bolts (1410 cc engine) Oil pump relief plug Engine mounting bolts and nuts: Flexible Flexible

mountings to crossmember mountings to brackets

Brackets to crankcase Transmission mounting bolts and nuts: Flexible mounting to frame

mounting to bracket Mounting bracket to transmission

Flexible

Damper Damper

53 15 53

20

3

4

4

6

72

38 25 100 30

52

34 136

40 56 10 36 22

41 7

26 16 4

belt tensioner bolts

Sump oil pan bolts Sump drain plug Oil pump cover screws (1410

35 55 72

26

40

rod bracket bolts

6

44

60

6 13 13 17

8 18

18

24

10

14 17

12 15 18

20 25 48

35

40 25 68

29 18

50

40 34 25

29 25 18 16

22

rod pivot bolts Clutch bellhousing or torque converter housing to engine:

29

40

Flange bolts Bolts with washer Clutch cover bolts

35 25

48 34 20

Part

A 1410

15

cc (86 cu

in)

engine

General description

1

The valve gear comprises heat

The engine It

is

is

transversely

resistant steel valves, coil springs

of the four cylinder, in-line,

and

mounted

The pistons are of tapered skirt elliptical type fitted with three piston rings - two compresssion and one oil control. The gudgeon pins

at

overhead camshaft type. the front of the car as an assembly in

conjunction with the transmission. The camshaft is supported in three bearings and it is driven by a toothed belt from a sprocket on the crankshaft. The camshaft has an integral drivegear for driving the distributor and also incorporates an eccentric cam for operating the fuel pump. The rocker gear comprises separate shafts for the intake valves and the exhaust valves. The design of the rocker arm differs according to which type of valve it is operating. On North American models, the intake rocker arms operate two valves per cylinder, the extra one being the jet valve, which is fitted as an aid to exhaust emission control.

split retaining collets. Oil

seals are located

in

the valve guides.

are press fitted in the connecting rods but are floating

The crankshaft

is

in

the pistons.

main bearings. the front and rear ends. The centre main

a steel forging supported

on

five

It is fitted with an oil seal at bearing shells incorporate thrust flanges to control endfloat. The lubrication system is based upon an oil pump driven from the front end of the crankshaft. The pump is of eccentric gear type and incorporates a pressure relief valve. The pressurised oil passes through a full flow, disposable, cartridge type oil filter which is screwed into the front face of the engine.

22

Fig.

V.

1 .1

Cutaway view

of the

1410 cc engine (Sec

1)

r

Fig.

23

1

.2

Cutaway view

of

1410 cc engine with N.American

specification (temperature controlled air cleaner

(Sec

1

and

catalytic converter)

Chapter

24

Engine

1

Check the valve clearances on completion as described

8 2

Major operations possible with engine

in

car

1

The following operations can be carried out without having remove the engine/transmission from the car. 1

Removal Removal Removal Removal Removal Removal Removal Removal Removal

and and and and and and and and and

3 1

2

3

4

4

Timing

- renewal

belt

first

is

be withdrawn

it

Release the alternator mounting and adjuster link bolts, push the and remove the drivebelt. Unbolt and remove the pulley from the water pump. Using a ring spanner on the crankshaft pulley bolt, set the locating pin on the crankshaft sprocket opposite to the TDC mark on the belt cover with No 1 piston at TDC on its compression stroke. This can be checked by observing that the contact end of the distributor rotor arm is opposite the No 1 HT lead 1

segment is

removed to gain access

components.

refitting

Remove

the breather hose which runs between the rocker cover cleaner casing. Remove the air cleaner. On models with a two piece timing belt cover, remove the top half. air

Unbolt and remove the rocker cover. It is recommended that the crankshaft

closed.

Unscrew the bolts which hold the rocker shafts 6 remove the rocker arm and shaft assemblies.

in

position

and

the distributor cap.

in

Unbolt and remove the timing belt cover. Release the belt tensioner pinch bolt, followed by the tensioner pivot mounting bolt. Lever the tensioner towards the water pump and retighten the bolts. This will have removed tension from the belt. 4 Slide the toothed belt from the camshaft puiley. 5 Remove the four small bolts from the crankshaft pulley. If the centre bolt is held while the small ones are unscrewed, the setting of the TDC mark will not be altered. Pull off the pulley, remove the timing belt from the crankshaft 6 sprocket. If it is to be used again, mark it with regard to the direction of running so that it can be refitted the correct way round; also as to tooth alignment with the sprockets. For inspection details of the timing belt and sprockets refer to Part 7 2 3

D

of this Chapter.

make

sure that the crankshaft has not been this, observe that the sprocket roll pin aligns with the projection on the front casing. If by any chance, the crankshaft sprocket has been taken off, make sure that the belt flange which goes behind it has its convex face against the sprocket

8

Before

fitting

moved from

its

the belt,

TDC

setting.

To check

(photo).

by reversing the removal operations. The exhaust and intake rocker assemblies have different types of rocker arms and they are not equally spaced so they cannot be interchanged. 7

Section

alternator in towards the engine

is now turned by means of the crankshaft pulley bolt until No 1 piston is at TDC. This can be verified by making sure that the notch in the pulley is aligned with the TDC mark on the timing index when both valves of No 1 cylinder are

5

in

rocker cover gasket.

to

of the rocker gear refitting of the camshaft refitting of the timing belt refitting of the cylinder head refitting of the engine oil sump refitting of the engine front casing and oil pump refitting of the pistons and connecting rods refitting of the flywheel* refitting of the crankshaft*

Rocker gear - removal and

and the

new

refitting

* As the transmission and clutch must recommended that the engine/transmission

to these

9 or 20 and use a

Refit the rocker gear

Check that the timing mark on the camshaft sprocket 9 alignment with the mark on the cylinder head (photo). 10 1

the timing belt, making sure between sprockets.

Fit

taut

is

that the tension side of the belt

in

is

Refit the crankshaft pulley.

it to move and to apply tension to the belt. Tighten the tensioner pinch bolt followed by the pivot bolt, to the specified torque. 13 Using a spanner on the crankshaft pulley centre bolt, turn the crankshaft through one complete turn (360°) and re-align the TDC marks. 14 Release the tensioner pivot and pinch bolts in that order and then

12 Release the tensioner bolts to allow

Fig.

1

.3

The rocker gear (Sec

retighten them in the reverse order. The belt should now be correctly tensioned (photo). 15 Refit the timing belt cover and the water pump pulley. Fit and adjust the drivebelt, by referring to Section 1 7.

3) Timing mark

Timing mark (Cylinder head)

(Crankshaft pulley

Timing mark

locating pin)

(Front case'

Timing mark (Camshaft

Timing mark

sprocket)

(Crankshaft pulley pin)

Fig.

1

.4

The sprocket timing marks (Sec

4)

25

Fig.

1

1

.5

Adjusting the timing belt tension (Sec 4)

Tensioner pivot bolt

2

Pinch bolt

Inset: tensioner spring

anchorage

V.

£^P|!

""" 4.8 The crankshaft sprocket (TDC) alignment

•

4.9 The camshaft sprocket alignment

•^"V

Crankshaft

Flange

sprocket

4.14 Timing

belt fitted

Fig.

1

.6

Crankshaft sprocket flange (Sec 4)

Chapter

26

1

Engine

Timing mark

Knock pin

(Camshaft sprocket)

Camshaft sprocket

Timing mark (Cylinder head)

Tension side

of belt

5.5a Method of holding the camshaft to stop Timing belt tensioner

Timing mark

Tensioner spring

(Front case)

Timing mark (Crankshaft sprocket)

Front case

Crankshaft sprocket

Fig.

1

.7

Timing

belt tensioning details (Sec 4)

5

Camshaft - removal and

1

Remove

refitting

the breather hose which runs between the rocker cover cleaner casing. Remove the air cleaner.

and the 2

5.5b Removing the camshaft sprocket

air

Disconnect the timing belt from the camshaft sprocket by removand releasing the belt tensioner as described in Section 4. There is no need to release the belt from the crankshaft 3

ing the belt cover

sprocket.

Unbolt and remove the rocker cover. Unbolt and remove the camshaft sprocket. Hold the sprocket still to unscrew the bolt by either passing a lever through the spokes of the sprocket or by gripping the square 'nibs' provided for this purpose on the camshaft (photo). Remove the rocker shaft assemblies as described in Section 3. 6 Unbolt and remove the small rectangular cover plate from the rear 7

4 5

of the cylinder

head (photo).

Unscrew and remove the camshaft anchor bolt and thrust casing 8 tightening bolt (photos). Remove the cooling system expansion tank. Withdraw the 9 camshaft and thrust casing from the end of the cylinder head which is nearest the flywheel housing (photo). 10 Refer

to

Part

D

of this

Chapter for inspection and renovation

details. 1

1

hole

is a reversal of removal but make sure that the threaded the thrust casing is aligned with the bolt hole in the cylinder Refit the timing belt as descrbed in Section 4. Tighten the

Refitting in

head. sprocket bolt to the specified torque (photo). Check and adjust the valve clearances as described 1 2 or 20.

in

Sections

5.7 1

The camshaft

thrust housing cover plate

it

from rotating

5.8a The camshaft anchor bolt

5.9

5.8b The camshaft thrust casing bolt

Removing the camshaft

5.1

1

Fitting the

camshaft thrust casing

r

Threaded hole

Camshaft thrust case tightening bolt

Fig.

1

.8

Removing the camshaft cover

plate (Sec 5) Fig.

^

1

.9 Fitting

the camshaft. Note the thrust casing bolt holes (Sec 5)

Chapter

28

6.1

5a Fitting the cylinder head gasket

6.1

5b

1

Fitting the cylinder

Engine

head

6.1

5c Tightening the cylinder head bolts

A

Crankshaft pulley side

6

(fey

©

©10

©4

_ ©'„

©

^°)2

©5

3

J®1 l(Q

^

I Fig.

1.10 Cylinder head bolt tightening sequence (Sec 6) Fig. 1.11

6

Cylinder head - removal and refitting

Drain the cooling system as described in Chapter 3. Remove the air cleaner. Disconnect the engine upper stabiliser/damper by unscrewing its forward pivot bolt. 1

Sealant application areas for

17 The timing belt is refitted as described 18 Fill the cooling system and check that been reconnected.

sump fitting

in all

(Sec 7)

Section 4. wires and hoses have

2

3

Remove

4

Disconnect the radiator upper hose from the cylinder head. Disconnect the brake servo vacuum hose from the intake mani-

5

the rocker cover.

fold.

6 7

8

Disconnect the fuel hoses from the carburettor. Disconnect the heater and choke heating hoses. Pull the HT leads from the spark plugs, take off the distributor cap

and place

it

to

one

side.

Disconnect the LT lead and vacuum pipe from the distributor and remove the distributor (see Chapter 4). 10 Unbolt and remove the intake manifold. Pull it away carefully without straining the accelerator control cable and tie the complete assembly with carburettor to the bulkhead. Unbolt the heat collecting cowl and the exhaust manifold. Release 1 1 the downpipe bracket. Provided the manifold is pulled carefully forward on the flexible mounting of the exhaust system, it will clear the cylinder head and can be wedged or tied back. 12 Release the timing belt from the camshaft sprocket as described in Section 4. 13 Unscrew the cylinder head bolts evenly and progressively by reversing the sequence shown in Fig. 1.10. The bolts are of socket headed type and a hexagon (Allen key) type wrench will be required. 14 For complete dismantling and renovation of the cylinder head, 9

refer to Part

D

of this Chapter.

Refitting is a reversal of the removal operations but make sure that 1 5 the head and block surfaces are absolutely clean and use a new gasket without jointing compound. Tighten all bolts progressively to the specified torque in the sequence shown in Fig. 1.10. Use new gaskets for the manifolds and apply sealant round the coolant hole in the gasket for the intake manifold (photos). 16 Adjust the valve clearances (Sections 19 or 20) and after refitting the distributor, check the ignition timing (see Chapter 4).

7

Engine

sump - removal and

refitting

1 Raise the front of the car on ramps or axle stands and drain the engine oil.

Unscrew and remove the sump securing bolts. 2 Remove the sump, clean it out and scrape away all old pieces of 3 gasket from the mating flanges. Refitting is a reversal of removal. Use a new gasket but before 4 fitting it, apply sealant to the crankcase flange as shown. Make sure that the drain plug is fully tightened. 5

8 1

2

Engine front casing and

Remove Remove

oil

pump

- removal and

refitting

the timing belt as described in Section 4. the engine oil sump as described in the

preceding

Section.

Peel away and remove the now exposed sump gasket. 3 Unscrew and remove the securing bolts from the front casing and 4 withdraw the casing complete with oil pump, pick-up pipe and filter (photo).

5 Refer to Part D of this Chapter for details of oil pump overhaul and casing oil seal renewal. Refitting is a reversal of the removal procedure. 6

9 1

2

Pistons and connecting rods - removal and refitting

Remove Remove

filter

screen.

the cylinder head as described in Section 6. the engine sump (Section 7) and the oil pick-up pipe and

8.4

9.

1

Removing the

1

a

A

front casing with the

oil

pump

piston with ring compressor

9.1 2 Fitting a piston

and connecting rod to the cylinder block

9.4 Making the big-end identification marks

9.1

1b The piston crown directional arrow

9.1

3a

A

connecting rod bearing shell

Chapter

30

9.1

3b A connecting rod cap bearing

1

Engine

9.1

shell

3c Tightening

a

big-end bearing nut